Support with prototype development & small-lot production

At NC Network Inc., we help you outsource production of parts and OEM products.

Our technical staff connects your business with manufacturing contractors within our network of over 18,000 manufacturers with excellent technology. We have a track record of commissioning the production of prototype and development parts and mass production parts for major automobile and medical equipment manufacturers.

Strength of NC Network

Commitment to quality

Each of our staff has extensive experience in the field, and can matche production contractors for your parts. Our team includes a processing manufacturer manager both in Japan and the United States, an engineer in an automobile manufacturer, and a quality assurance manager for an electronics maker. We actually visit and confirm the site, request processing, guarantee the quality and deliver it. In cooperation with Factory Network China (formerly NC Network China), production can be outsourced to a factory in China as well.

Contact us if you have any of the following issues. We will make appropriate proposals for improvement.

- – A need to shorten delivery time

Achieve reduced delivery time in line with your requirements. - – Technical issues

We will help you solve issues that existing subcontractors have not been able to solve. - – Cost issues

We will solve cost reduction issues that were not realized with existing outsourced partners.

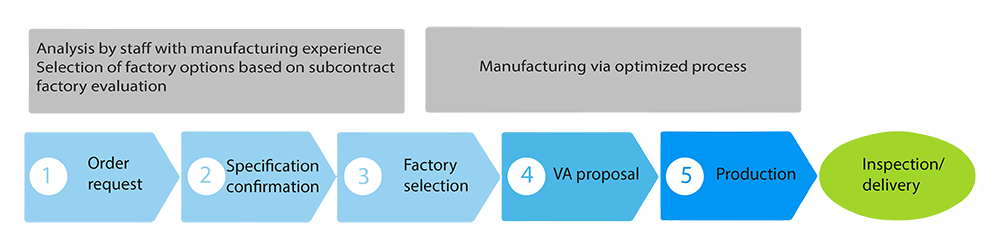

Business flow

Technical staff with experience in each field as well as external technical advisors will check specification and select a factory for you. We will also make Value Analysis proposals as needed.

Subcontract factory

From the customer database of more than 17,000 EMIDAS members, technical staff will select a few factories suitable for the specific request and will visit the factories to confirm.

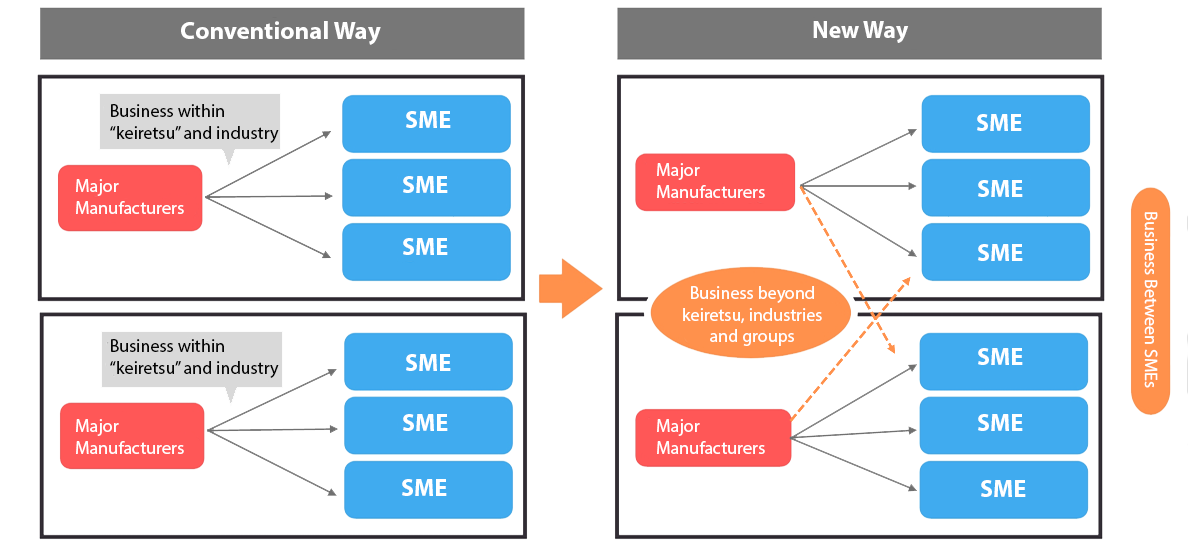

Concept for factory selection

Utilizing a cross-section of manufacturers makes business beyond keiretsu and industries possible, creating better value and enhanced capabilities.

Quality assurance

Flowchart of quality management (for mass production)

Evaluation of subcontractor factories

We work together to compile the necessary qualifications for your business in order to determine the best contractors. We make sure there are no discrepancies in evaluations among our technical staff.

To be specific, our staff visits subcontractor factories on a regular basis with our unique “evaluation entry sheet.” We report the actual results to factories from four aspects: company’s mindset (M), cost (C), quality (Q) and delivery date (D).

Depending on the product, all four evaluation aspects are added up to ensure the right manufacturing option. If some aspects are lacking, our technical staff strives to work with the selected factory to meet your requirements.